Viva Energy and Cleanaway team up to address hard-to-recycle plastic waste

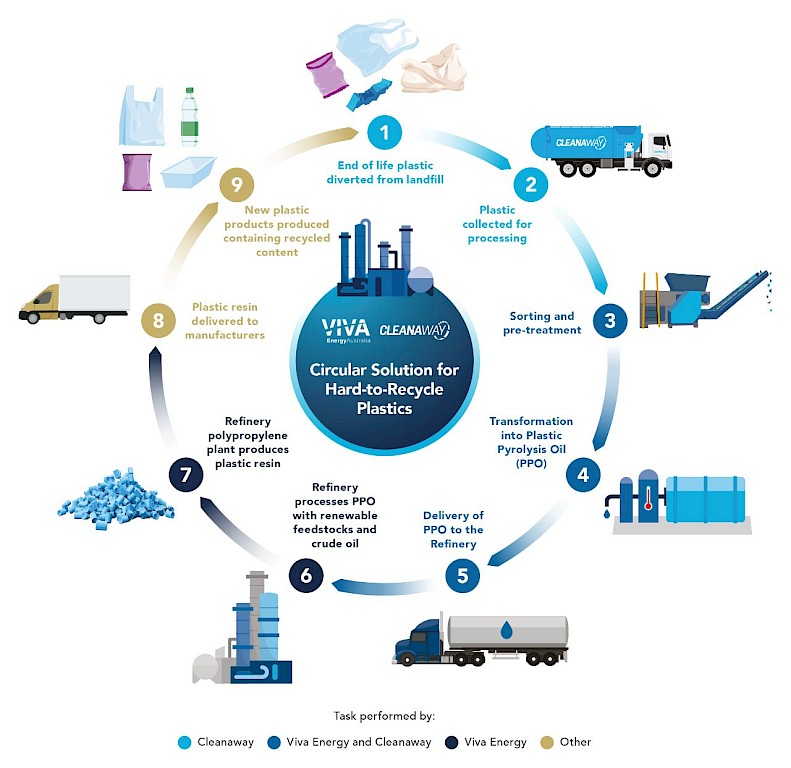

Cleanaway and Viva Energy today announced they have entered into an agreement to undertake a pre-feasibility assessment of a circular solution for soft plastics and other hard-to-recycle plastics currently sent to landfills and transform them back into feedstock for food-grade plastic resin.

Cleanaway and Viva Energy today announced they have entered into an agreement to undertake a pre-feasibility assessment of a circular solution for soft plastics and other hard-to-recycle plastics currently sent to landfills and transform them back into feedstock for food-grade plastic resin.

The partners want to provide a sustainable soft-plastic solution for food manufacturers and packaging specialists seeking to cater to the growing environmentally conscious market, as well as households and businesses who want a landfill-diversion option.

The facility being assessed would incorporate a dedicated sorting and mechanical pre-treatment plant and an advanced chemical recycling plant to convert waste plastic into plastic pyrolysis oil (PPO), a feedstock for co-processing at Viva Energy’s Geelong Refinery. Recycled plastic manufactured through this process would have identical properties to virgin resin, opening the potential for food manufacturers to use recycled packaging.

The project could provide an important solution for food manufacturers and packaging specialists to meet their obligations under the Australian Government’s new recycling regulatory scheme that is expected to be in place by the end of 2025. Implementation of the packaging reform with mandatory obligations and a product-stewardship scheme for soft plastics are critical to enable this investment.

This project follows Viva Energy’s announcement in May last year that it intends to introduce co-processing at its Geelong Refinery as part of it’s plans to transform the site into a broader energy hub. Co-processing will allow the refinery to demonstrate the important role it will play in plastic recycling while also reducing the facility’s carbon footprint.

For Cleanaway, pursuing this opportunity is part of its broader focus on providing low-carbon, high-circularity solutions that reduce the need for virgin resources and lift Australia’s recycling rates. Assessing the potential for a circular solution for soft and other hard-to-recycle plastics follows Cleanaway’s recent investment in three Circular Plastics Australia recycling plants in Melbourne and Albury which process PET beverage bottles, milk bottles, and other plastic packaging to create food and non-food grade resins to make new packaging.

Viva Energy Chief Business Development and Sustainability Officer Lachlan Pfeiffer said the project offers a significant advance in addressing Australia’s plastic waste issue.

“For Australia to have the ability to recycle its own plastic – a truly circular economy – we need to have a facility like this to convert waste plastic to pyrolysis oil on a commercial scale,” Mr Pfeiffer said. “If feasible, over time it will support a market for plastic collection and processing while also providing the pyrolysis oil we need to allow the refinery to produce recycled food-grade plastic. It will be a true end-to-end solution for manufacturers.”

“This strategic alliance forms an exciting foundation on which to pursue a circular solution for soft plastics. It brings together Cleanaway’s experience and strategic infrastructure in the waste collection and processing sector, with the processing capability of Viva Energy’s refinery and polypropylene plant.”

Cleanaway Executive General Manager, Strategy, Mergers & Acquisitions, Frank Lintvelt said: “This is an exciting opportunity for Cleanaway to expand our existing operations enabling plastic and packaging circularity in Australia. We are looking forward to leveraging our experience piloting new collection methods for soft plastics alongside Viva Energy’s refining capability.

“An end-to-end circular solution for soft plastics is desired by many of our customers, consumers, and governments. We are keen to progress this early-stage planning work so that once we have a federally harmonized policy framework for plastic packaging and mandatory obligations for packaging design, recovery, and recycled content – together, we can provide a circular plastic packaging solution in Australia,” said Mr Lintvelt.

Viva Energy Media Enquiries

Michael Cave

T: +61 409 647 910

E: michael.cave@vivaenergy.com.au

Cleanaway Media Enquiries

Mark Biddulph

T: +61 499 332 601

E: mark.biddulph@cleanaway.com.au

About Cleanaway

Cleanaway Waste Management Ltd (ASX: CWY) is Australia’s leading waste management company with a national network of unique collection, processing, treatment, and landfill assets. Cleanaway operates from more than 350 locations and employs more than 7,600 people. Our philosophy is that all waste is a resource and we aim to incorporate recovery, recycling, and reuse throughout our operations and those of our clients. Our mission is to make a sustainable future possible together.

Circular Plastics Australia (PET) is a joint venture partnership between Pact Group, Cleanaway Waste Management Ltd, Asahi Beverages, and Coca-Cola Europacific Partners (CCEP). Circular Plastics Australia (PE) is a joint venture partnership between Pact Group and Cleanaway Waste Management Ltd. For more information: https://www.cleanaway.com.au

About Viva Energy

Viva Energy (ASX: VEA) is one of Australia’s leading energy companies and supplies approximately a quarter of the country’s liquid fuel requirements. It is the exclusive supplier of high-quality Shell fuels and lubricants in Australia through an extensive network of more than 1,330 service stations across the country.

Viva Energy owns and operates the strategically located Geelong Refinery in Victoria, and operates bulk fuels, aviation, bitumen, marine, chemicals, polymers, and lubricants businesses supported by more than 50 terminals and 55 airports and airfields across the country. For more information: www.vivaenergy.com.au

You can return to the main Market News page, or press the Back button on your browser.